Brief

In fall 2022, I joined the Brown Formula SAE Team as a co-lead and main modeler in the body subsystem team. During the shop practice, we are designing a body to solve the engineering problems, focusing on manufacturibility, meanwhile we are exploring the possibilities to use natural materials to seek possibility of sustainability.

Type

Duration

Skill practiced

Automotive Design

9.2022 - Ongoing

Modeling, design for manufactures, enginnering problem solving

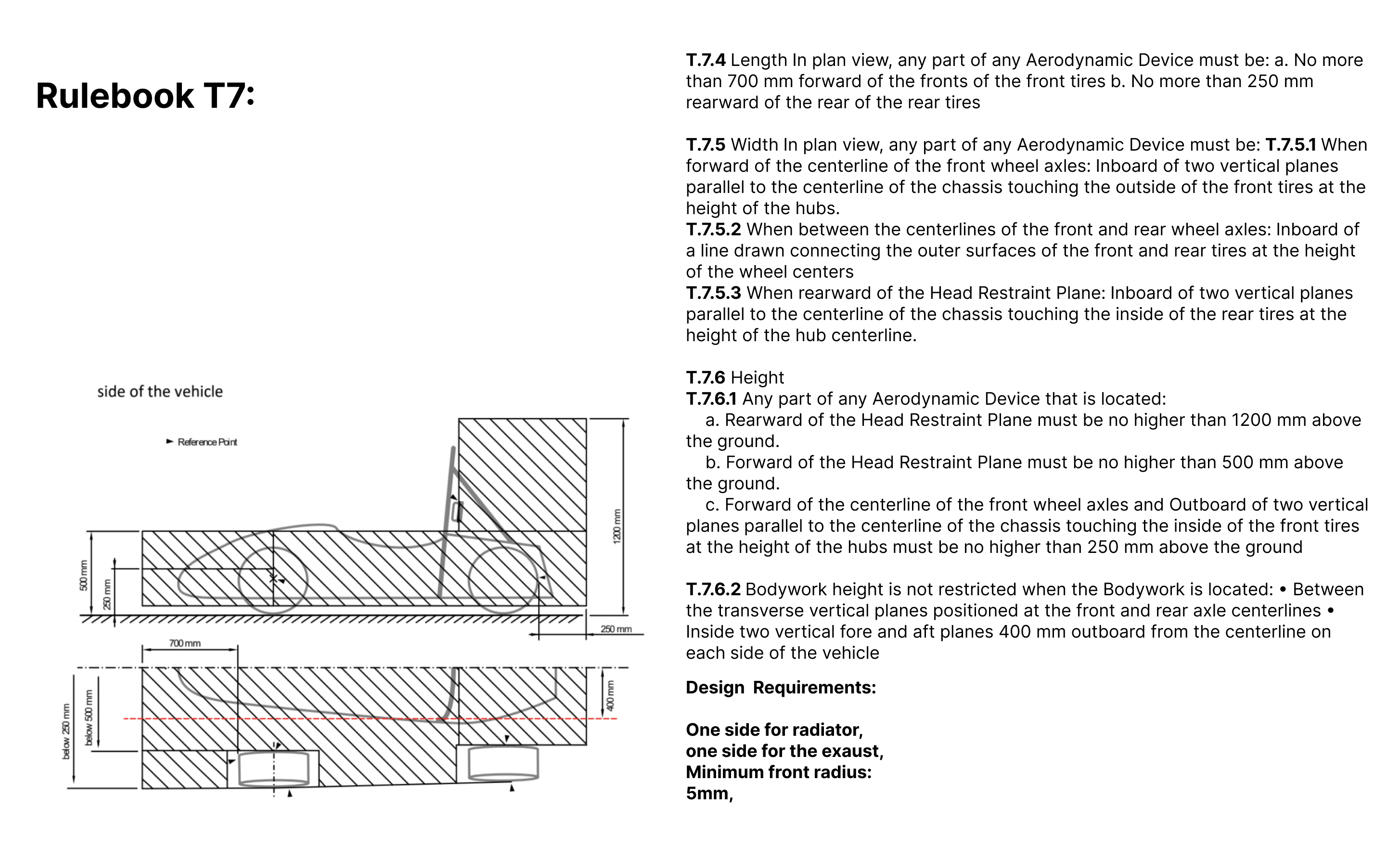

Initial research

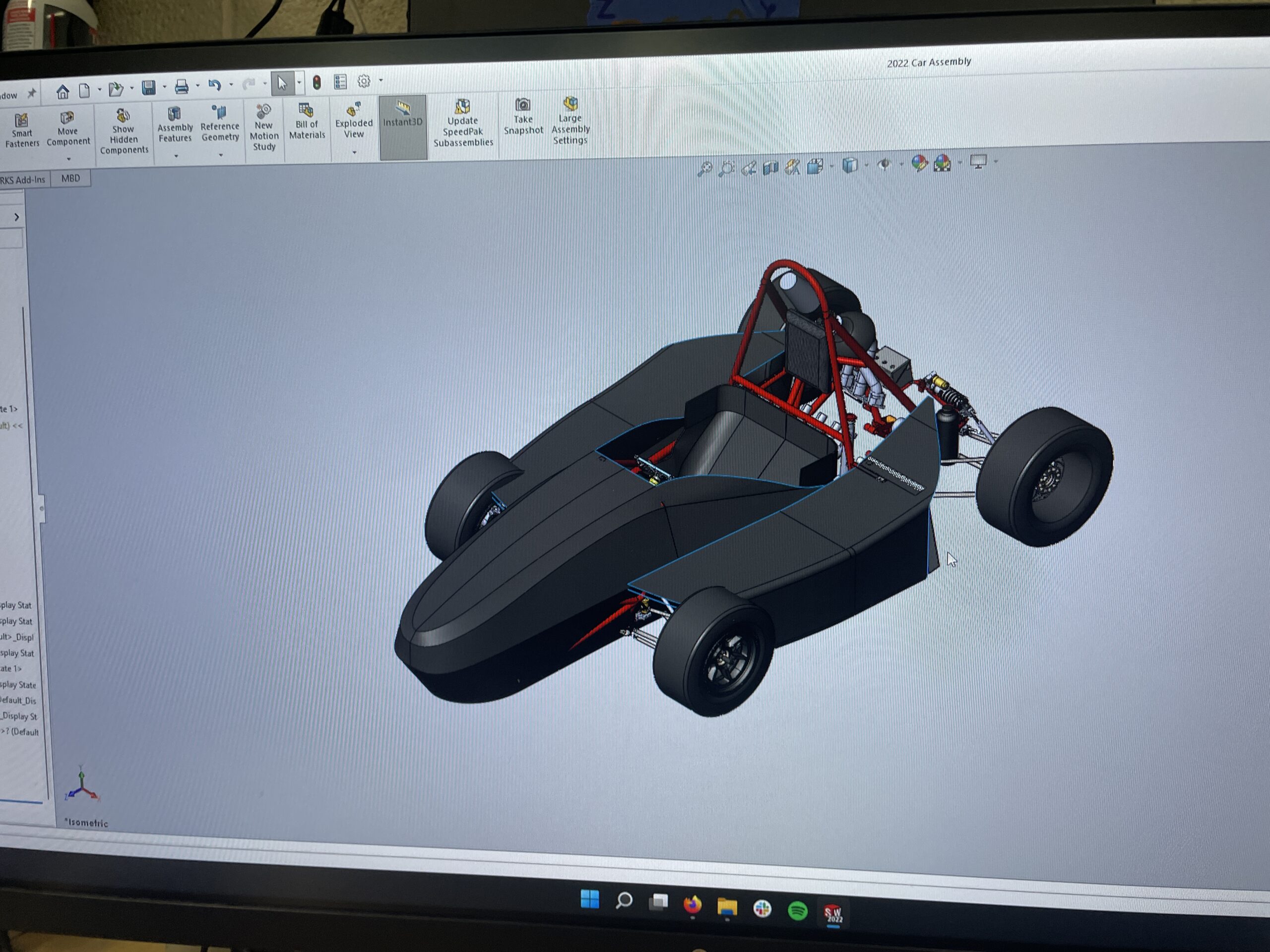

We start with examine the rulebooks and 2D sketch iterations. Our goal is to understand the engineering goal and limitations. And go with our creations to get a best looking Formula SAE racecar. We also use last year car as our reference to discover possible body form.

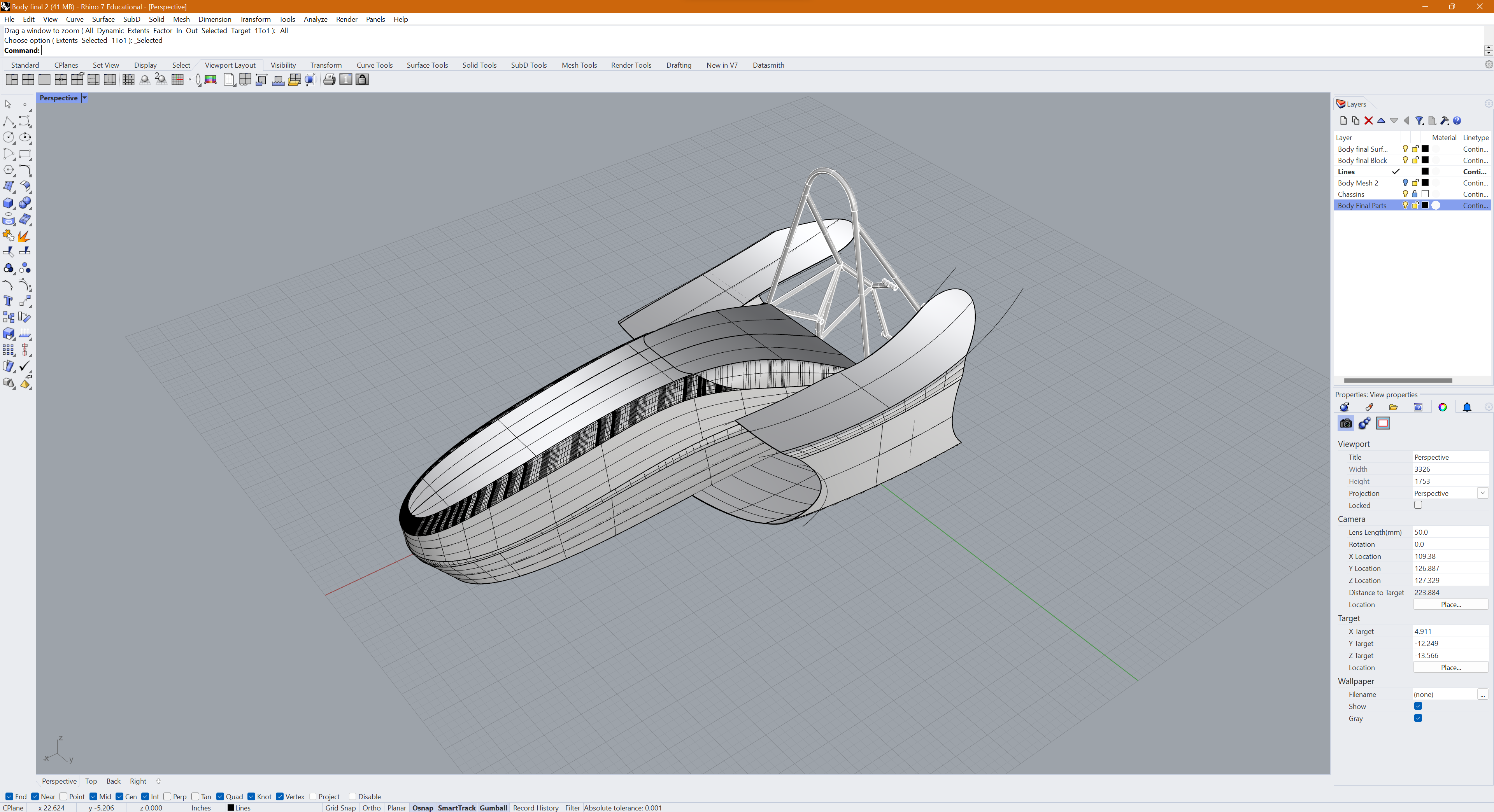

Modeling

One innovative way to do the modeling is that we start with VR. By using Gravity Sketch, it allowed us to quickly iterate the changes and get feedbacks from our engineering fellows.

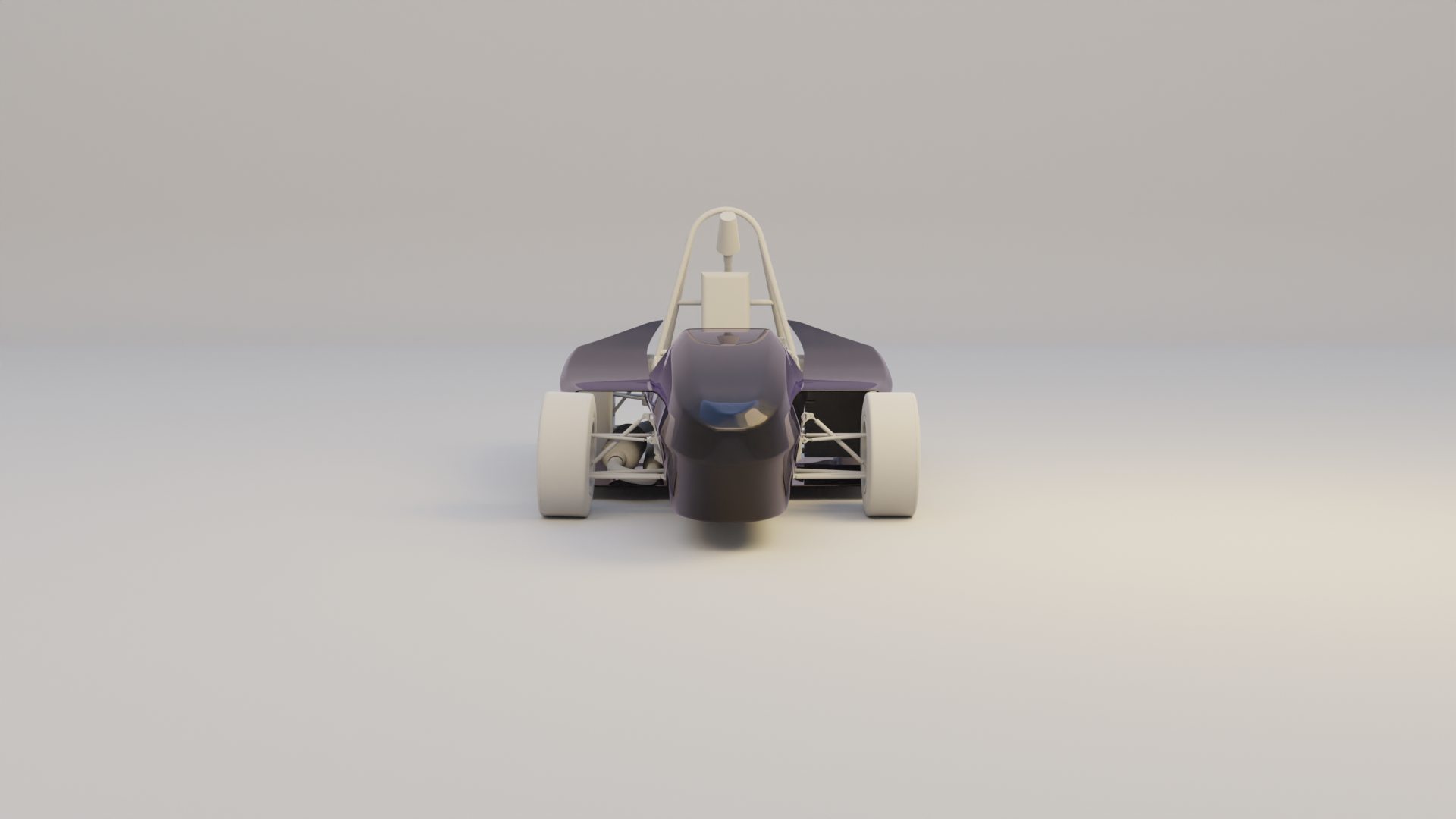

Later we used the VR model as a reference to build a few iterations of the body: I used Solidworks to work out the dimensions with other components. Then I moved to Blender to do the quick form prototyping and visualizations. Then I exported the mesh file to Rhino to do a detailed surfacing model. Finally I turn it back to Solidworks to do the assembly with other engineering models.

From this modeling experience I realized that modeling should be flexible and you need different approach to deal with different needs. Also this is a very valuable experience for me to think about how to work with engineers.

We are also working on some livery ideas using Photoshops

Manufacturing

This year,

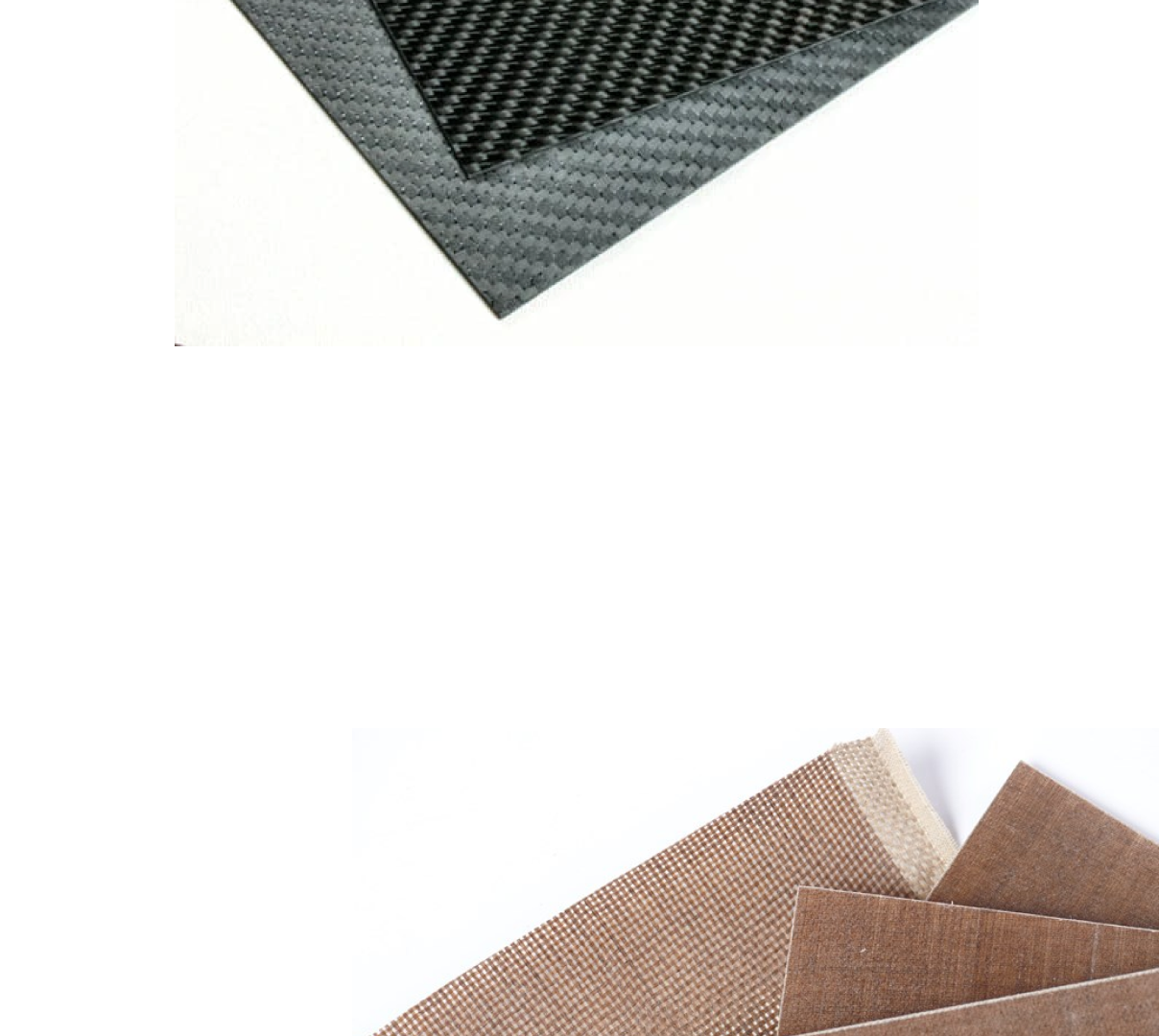

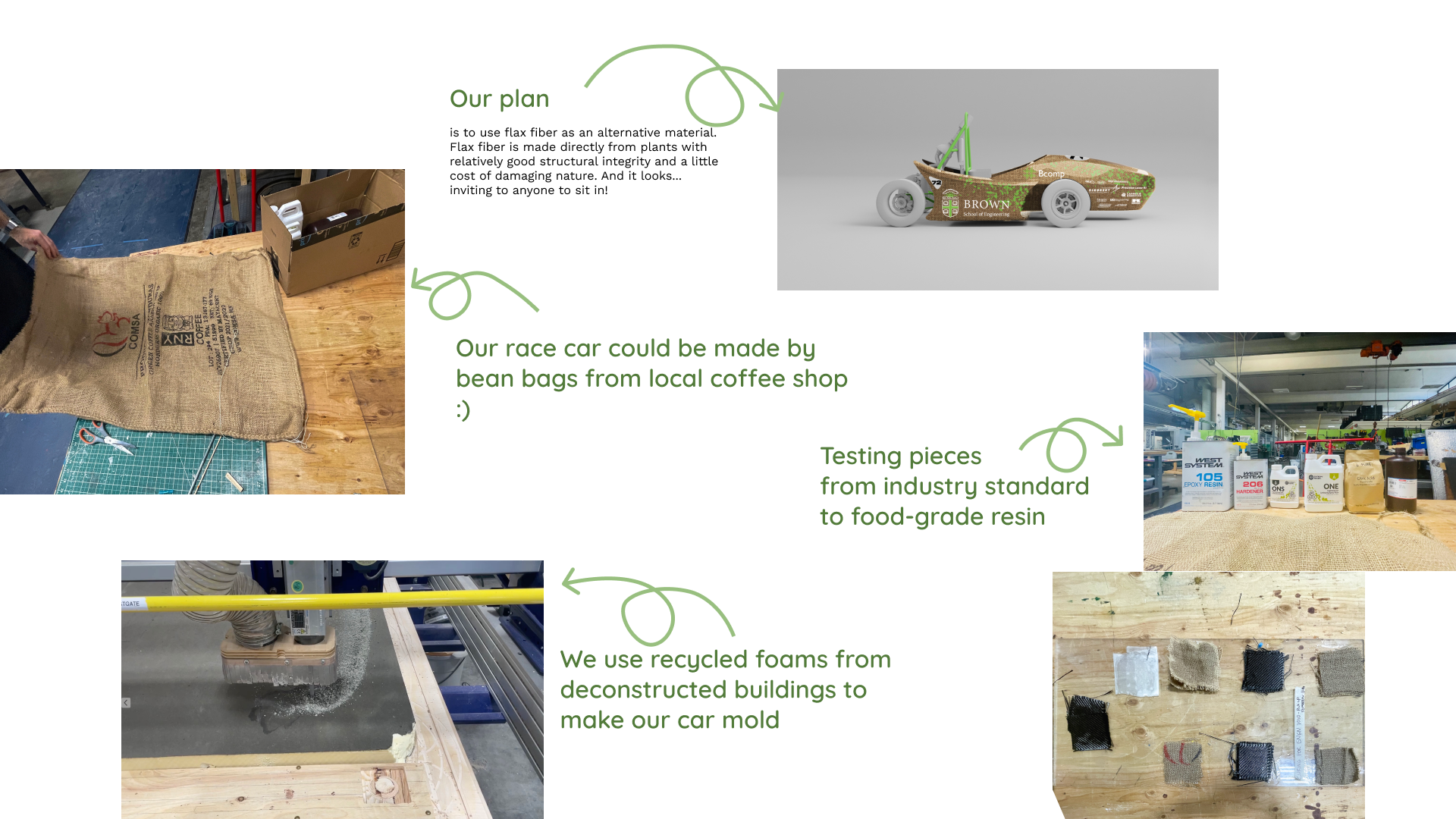

We want to achieve the next level of green and sustainability, and we are looking for a bio-composite manufacturing method with similar performance to our currently used carbon fiber.

Carbon fibers are widely used in the automobile industry as a strong and lightweight material. However, the production of such material is environmentally costly. The amount of resin used to strengthen the shape also burdens our nature. As a work-in-process goal, this year, we want to find a natural material we could use in body manufacturing. So we can achieve environmentally friendly, from the start of the factory.

to be continued...